Reduction of treatment costs by 30% through the recovery of resources and lower energy consumption.

Energy

Production of biogas and reduction of energy consumption by 70% compared to current systems.

Water Quality

Reduction of emerging compounds and pathogens by 70% through the use of membrane technologies.

Resource Efficiency

Reuse of 80% of the treated water and recovery of nutrients.

OBJETIVE

The main objetive is the design, construction and validation of a 12 m3/ day prototype for the treatment of two types of wastewater of different origin, urban and industrial.

The proper managment of waste water is one of the main challenges of the European Union. Its treatment is essential to ensure the protection of the environment and public health. At present wastewater treatment plants reduce the concentration of pollutants in these waters, minimizing the risk associated with the discharge of their effluents. However, the high energy and maintenance cost, as well as the high generation of associated waste, continue to be milestones to overcome.

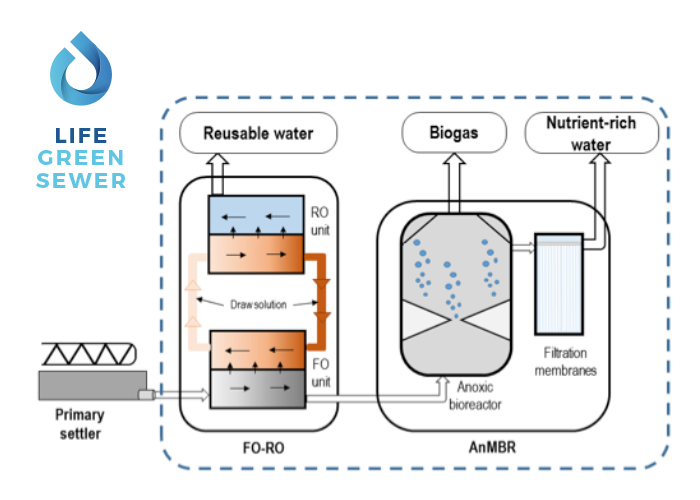

The LIFE GREEN SEWER project aims to validate a new secondary wastewater treatment system based on an integration of direct-indirect osmosis with an anaerobic membrane bioreactor, while alllowing the recovery of energy and resources, reducing the presence of pollutants, costs and energy consumption.

HOW IT WORKS

The proposed solution is based on a combination of membrane technologies that takes place in two stages: a preconcentration with direct-indirect osmosis and an anaerobic reactor with ultrafiltration membranes.

In addition, LIFE GREEN SEWER technology will have a monitoring and control system to record amount of biogas generated, optimize energy consumption, minimize water losses and reduce and monitor releases of emerging pollutants and pathogens.

EXPECTED RESULTS LIFE GREEN SEWER

CETIM – Coordinador del Proyecto

Parque Empresarial de Alvedro, calle H, 20

15180 Culleredo, A Coruña, España

Phone: +34 881 105 624

E-mail: info@cetim.es